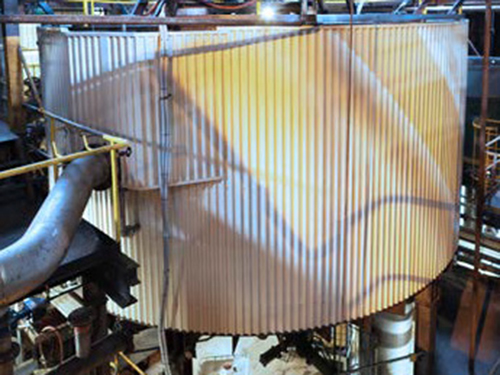

Sugar Research Institute’s High Performance Juice Clarifier design minimises sucrose degradation and the resources used to produce clear juice. Designed by SRI’s world-renowned experts, the SRI High Performance Juice Clarifier achieves low juice turbidity, high mud sink rate per unit volume and low flocculant usage to produce clear juice in the cane juice clarification process.

SRI’s improved clarifier design efficiently separates mud from the juice via an upgraded internal feed system that reduce peak circulation velocities in the separation zones of the clarifier.

With diameters from 5 to 14 metres, the SRI High Performance Juice Clarifier design effectively processes juice from 2,000 to 26,000 TCD.

SRI’s High Performance Juice Clarifier reduces juice short- circuiting, minimises mud up-flow and carryover, and limits inversion through shorter retention times. The core of the ‘improved’ clarifier design is the improved separation of the juice and mud at the separation zone which increases throughput for a given clarifier size while maintaining very low clear juice turbidity.

SRI High Performance Juice Clarifier design packages include (as required):

- Audit of existing juice clarification systems

- Design specifications for the:

- Clarifier body, flash tank and internals

- Flocculant preparation plant and addition system

- Lime saccharate preparation plant

- Upgrade of NG or SRT designs to the SRI HP Juice Clarifier

- Functional specification including control scheme for the juice circuit

- Operations manual

- Fabrication inspection

- Commissioning and operator training

Contact info@sri.org.au or our network of global affiliates for sales enquiries.